1 Building transport systems by aligning

with our customers

1 Building transport systems by aligning

with our customers

2 Transport system propriety technology

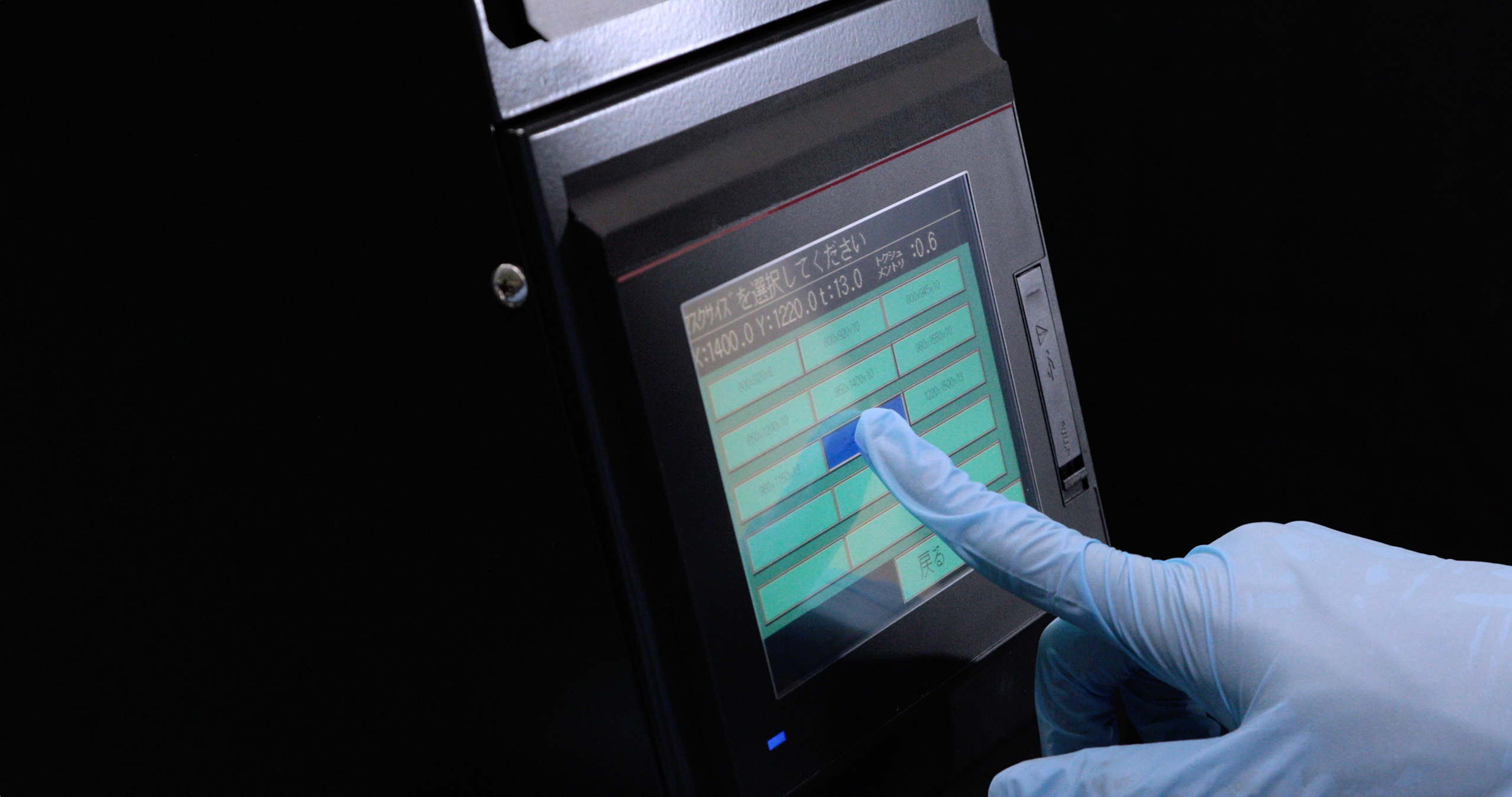

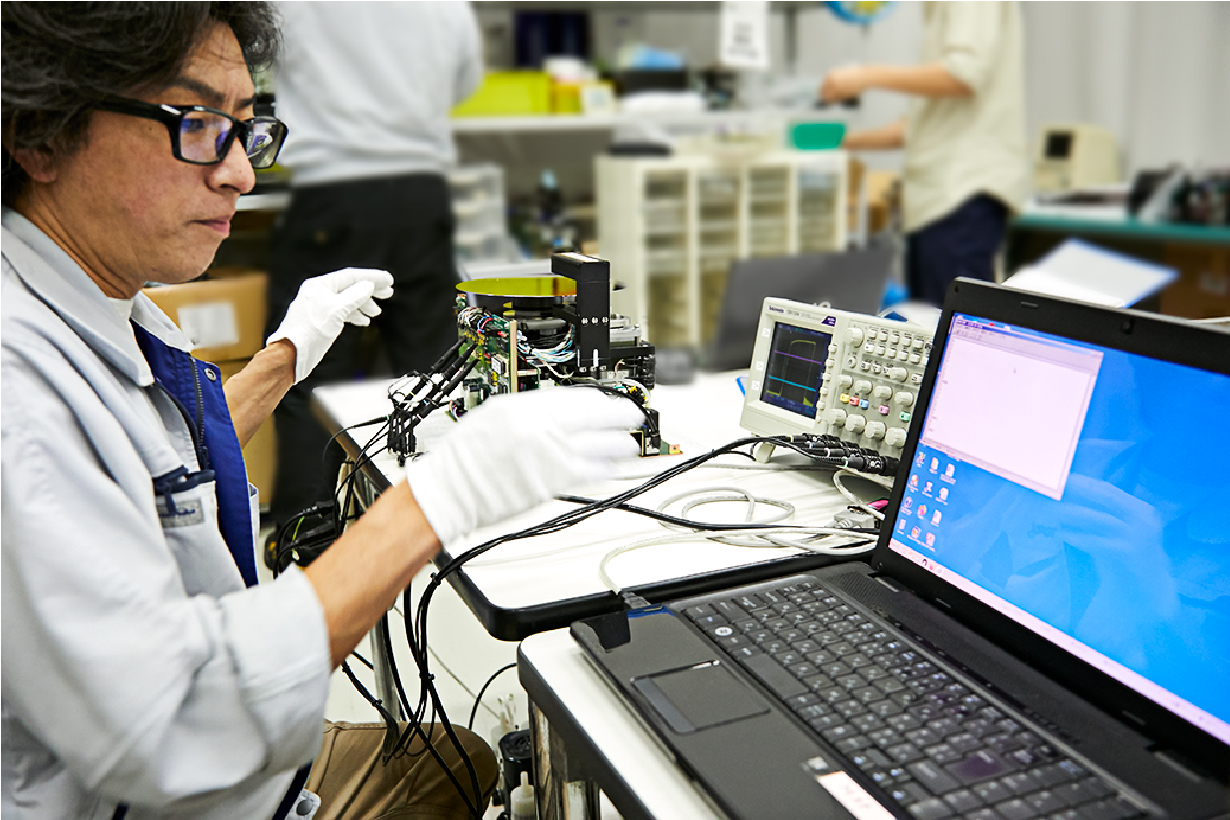

TEX E.G. has worked on transport systems for peripheral equipment related to liquid crystal displays and semiconductors for many years. The construction of our unique transport systems from development and design to production were born from our customer requests to “mechanize certain processes to improve efficiency”, “the heavy products are difficult to move, but to not use grandiose equipment like robots.” We solved the problem of declining human yields by utilizing our extensive experience in assist arms and silicon wafer transport equipment and our propriety technology from the customer’s point of view. Today we boast 70 % of the global share for systems that transports flat panels between equipment.

For example, trying to achieve high-accuracy transport using an assist arm unavoidably requires the device to become larger. To resolve this issue, we came up with the idea of using a guide unit called a catcher. Combining this with an assist arm made it possible to produce a small but highly accurate transport system.

When transporting heavy objects, the transport structure must be able to withstand this weight, but this in turn hurts operability. TEX E.G. utilized its proprietary technology to achieve smaller size and lighter weight to improve operability while also providing excellent performance.。

Rather than just meeting the customer’s requests, we utilize our extensive experience and technology to give priority to the people actually using the equipment to build order-made systems that best match the customer.。

Photomask Transport System

Pre-Alignment Unit ( WA Series )

We provide customization and can change specifications and technical applications to meet customer requests. Please consult with us.

Contact Form