Freely Control Temperature New Value Achieved Through Flexible Development.

Peltier Technology Applications

Quiet, Energy-Efficient Operation Within Restricted Space

TEXeg proprietary patented technology

Strict quality control

Wide range of engineers

Order-made development

Peltier Technology Applications

Flexible Response to Temperature Control and Adjustment Problems

Peltier technology possesses unlimited possibilities in the operations field of temperature manipulation and new developments are expected in the future. This technology is widely used in the transportation, storage, and cold and heat insulation sectors. We are committed to continuous research and development to solve various temperature related concerns.

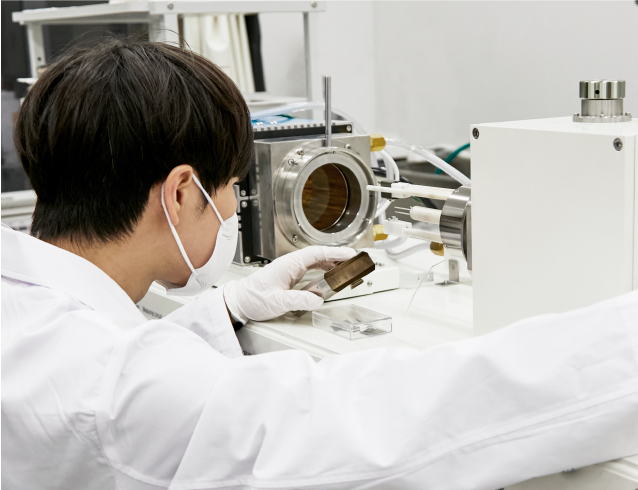

Quiet, Energy-Efficient Operation Within Restricted Space and

Under Fixed Conditions. Development of Compact Products Utilizing Peltier Characteristics

Ultra-small elements, the major characteristic of Peltier technology, can express both cold and hot at the same time. This is the secret to fully utilizing the potential of this technology under limited space and restricted conditions. TEXeg has experience not only with products that maintain cold temperatures, but also with those that maintain a constant temperature. We seek to understand the world’ s problems and requirements and then maximize the use of our technology to resolve and meet them.

TEXeg proprietary patented technology

Increasing the life of Peltier Products

TEXE.G. develops products utilizing its proprietary patented technology. Our propriety technology is the key to achieving durability. Our patented technology “stress attenuation structure” that provides excellent impact durability has successfully extended the life of Peltier products, which are known to break easily.

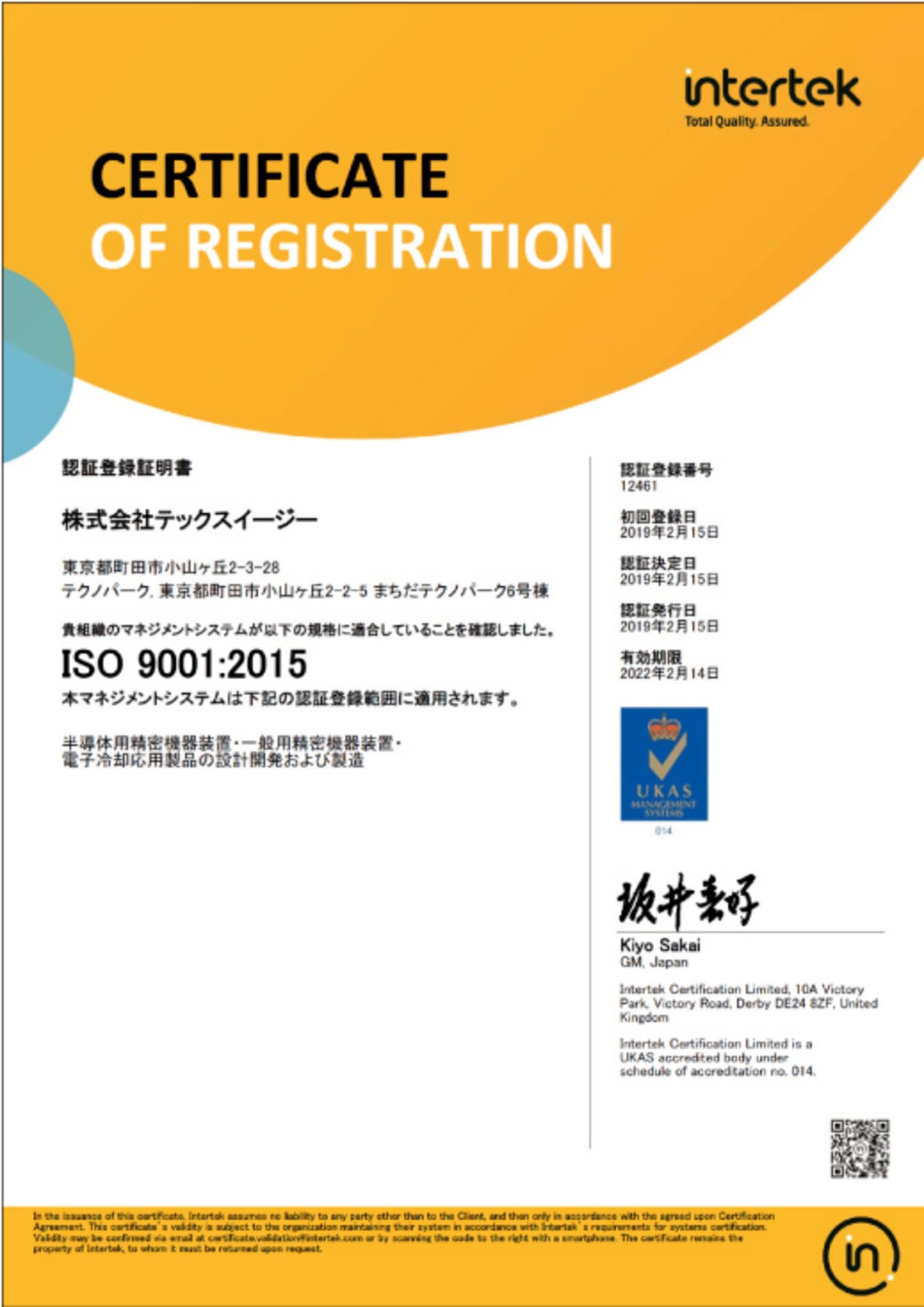

Strict quality control

Reliable Quality of a Domestic Manufacturer

ISO9001 Compliant Quality Control

● Fundamental Policy

Our corporate philosophy calls for strict compliance with laws and regulations, making sure employees are aware of the importance of satisfying customer requirements, and providing high-quality products and services based on the latest technology. We also set quality targets and conduct reviews to continuously improve the management system and achieve the objectives of the quality policy. We work with you to solve the problems and issues you face.

● What is ISO9001?

This is a standard set by the International Standards Organization (ISO) to ensure the quality of products and services and to improve customer satisfaction. It prescribes the requirements for building a quality management system. The integrated quality management system operated by TEX E.G. obtained ISO9001 certification in March 2018. The company continues to focus on quality management based on ISO9001 to continuously strive to provide high-quality products and greater customer satisfaction.

● Quality Targets

- We conduct proposal activities that increase customer value.

- We propose products and services that satisfy our customers while strictly observing the quality and delivery deadlines they require.}

Wide range of engineers

We actively hire engineers from overseas as well as in Japan to build a creative community. The global perspective and teamwork of our richly individualistic employees keep us working at the leading-edge of technological development.

Order-made development

By proprietary technology, gives “form” to customer desires.

● Ability to Meet Requests

We sincerely strive to solve the issues and meet the requests of customers. We actively take on the challenges-even development that is thought to be difficult.

● Accept Small Lot Production

If another company has turned down your small order saying it is not profitable, please talk to us. TEXE.G. accepts orders for small lots.

● Proposals Utilizing Our Expertise

We utilize our broad experience working closely with customers and our rich expertise to offer optimum solutions.

● Integrated System from Development to Mass Production

Based on our ISO compliant quality system we operate an integrated system from development to mass production to flexibly meet the needs of our customers.

《 Flow Up to Delivery 》

Step 1

Fact-Finding

Step 2

Plan Proposal

Step 3

Product Specifications Study

Step 4

1st Prototype Production

Step 5

2nd Prototype Production

Step 6

Verification

Step 7

Final Trial Production

Step 8

Verification

Step 9

Production